The first truly autonomous and productive robotic system, a step towards a more efficient and secure pharmacy

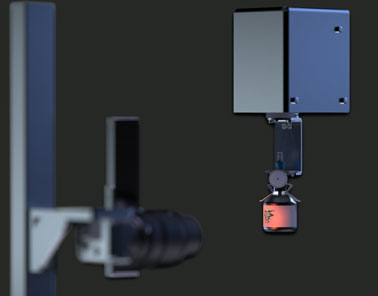

- Class II Biohazard Safety Cabinet Guaranteed vertical laminar flow in all areas of the system

- Class II Biohazard Safety Cabinet Guaranteed vertical laminar flow in all areas of the system

- Rotating Pre-loading WarehouseFor containing drugs and final containers in various formats

- Internal Barcode ReaderFor the control of materials to be loaded into the machine

- Final Product Warehouse For containing products in IV bags/rigid containers

- Ready-to-Use Syringe Storage WarehouseFor containing doses in syringe format

- Dosed Syringes Warehouse For loading syringes in multiple formats (1ml – 50ml)

- Operator Workstations

- Operator Workstations

Elevate your pharmacy's efficiency and safety with Janez Twin

Higher Hourly Productivity

Janez Twin delivers 40 precise doses per hour, catering efficiently to peak times and enhancing patient care

Operational Autonomy

Needle-free

Flexibility

Discover the future of pharmacy automation

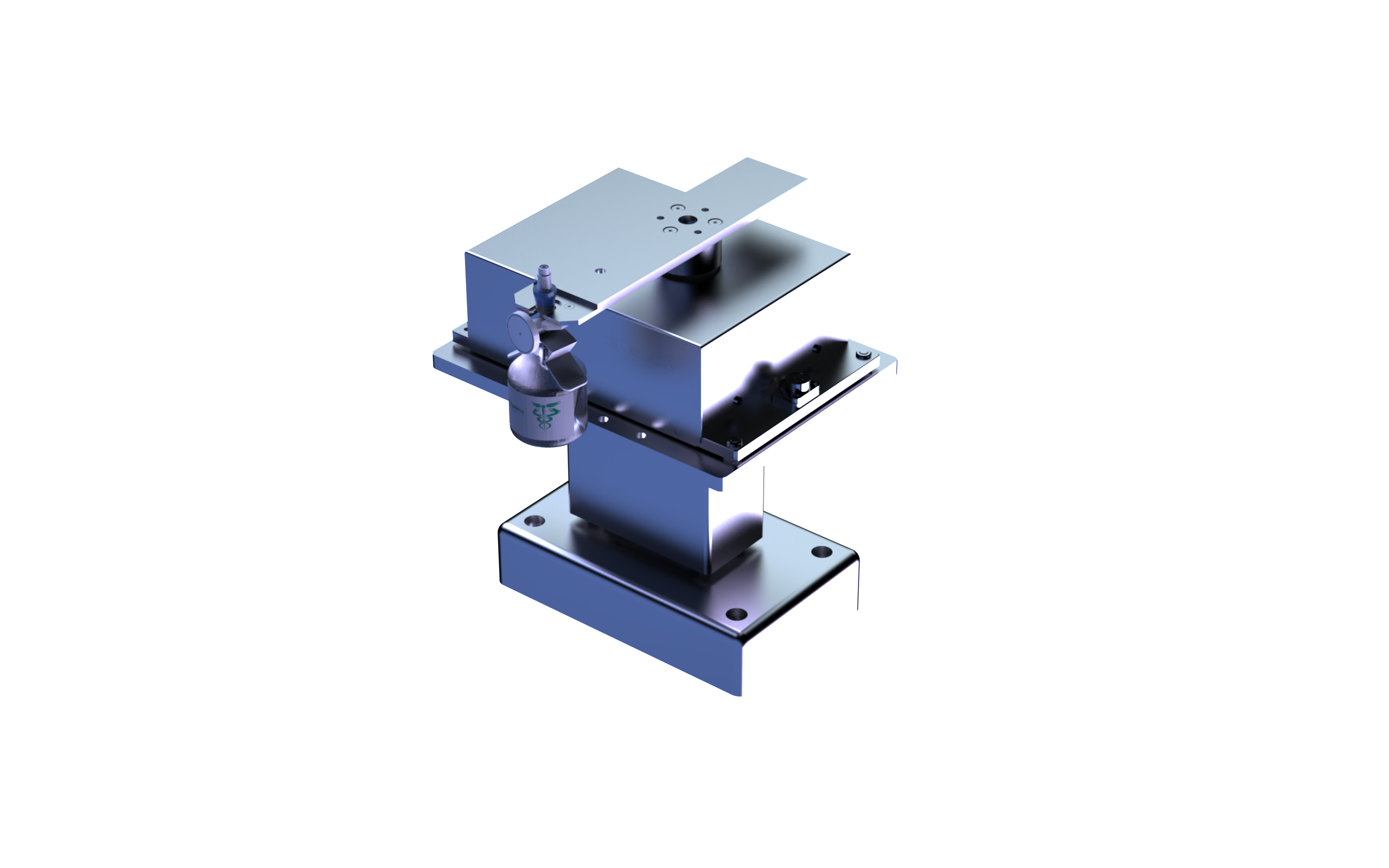

- Sanitization SystemAtomized Hydrogen Peroxide

- Dosing SystemAccuracy 0.1mm

- Infusion System

- Vision System for Syringe Barcode Control

- Robotic arm

- Robotic arm

- Vision System for Drug/Diluent Control

- Peristaltic pumpsFor managing the overfilling of diluents

- Gravimetric Control for Drugs/SyringesResolution 0,01 mg

- Gravimetric Control for IV Bags/Rigid Containers

Features

WAREHOUSE

A five-level rotating warehouse stores up to 132 vials and 62 diluent IV bags blank

Specialized Syringe Storage: An exclusive warehouse for syringes maximizes space and storage capacity.

PRE-LOAD

Workflow Optimized: Fully pre-load materials for immediate compounding upon prescription arrival, enhancing efficiency.

VERSATILE MATERIAL SUPPORT

No Special Compounding Materials Required / Broad Range Compatibility: Accommodates various containers, including IV bags (50-1000 mL), syringes (1-50 mL), and elastomeric pumps

REMOTE MONITORING

Intuitive RGB LED System:

• White Lights: Machine operating correctly.

• Orange Lights: Brief intervention needed soon; system still functional.

• Red Lights: Immediate intervention required; machine stopped.

SIMPLIFIED CLEANING AND DISINFECTION

• Easy Access: Automatically opens for effortless cleaning.

• Advanced Sanitization: Utilizes atomized hydrogen peroxide for effective decontamination.

HASSLE-FREE INSTALLATION

• Modular Design: Comprises six easy-to-install modules.

• Mobility: Equipped with wheels for convenient maintenance.

• No Mandatory Exhaust Connection: Flexibility in installation without needing building ductwork.

COMPREHENSIVE STATISTIC TOOLS

• Insightful Reports: Technical summaries for prescriptions and compounding.

• Customizable Analytics: Tailored tools to meet specific pharmacy requirements.

SEAMLESS SOFTWARE INTEGRATION

Universal Compatibility: Integrates with any hospital prescription software using various protocols and standards.

Cost Savings

Reduce expenses with our zero drug residual strategies and minimize outsourcing needs.

Unmatched Accuracy

Advanced technologies ensure precise doses, with vision cameras and multiple gravimetric controls eliminating manual errors.

Empower Your Staff

Protect staff from repetitive stress and hazardous exposure, focusing them on quality work.

Continuous, Qualified Assistance

A partnership that grows with you, ensuring top-tier support.

Find out more

INNOVATION FOR THE FUTURE OF AUTOMATED COMPOUNDING

+39 02 92109950

Via Firenze, 6/a

Cernusco sul Naviglio

20063 Milan

Italy

info@solipharma.it